Multi-mode ion source for organic and inorganic sputter depth profiling

The multi-mode gas cluster ion source is designed to operate in both Arn+ cluster and Ar+ monatomic modes making it suitable for sputter cleaning and depth profiling organic, inorganic and metallic thin films. In addition it may also be used to generate low energy He+ ions for use with ion scattering spectroscopy.

The use of large argon clusters for sputter depth profiling of organic materials is now widely accepted and their use is being extended to inorganic depth profiling.

Through a combination of cluster size and acceleration voltage a wide range of materials may be sputter cleaned or depth profiled without chemical damage of the surface. The ion source can be used in monatomic mode for thin metal layers, small clusters at high beam energies may be used for metal oxides and large clusters at low to medium energy for a wide range of organic materials.

Arn+ gas cluster operating mode

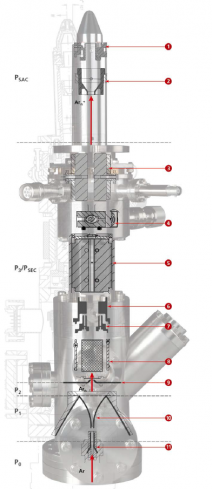

Large Ar clusters are formed by isentropic adiabatic cooling of the gas as it expands from high pressure (P0) through a nozzle into the vacuum of the source region (P1 / P2). The Arn clusters are ionised by electron impact, extracted from the source region and accelerated along the ion column where a Wien velocity filter is used to select a median cluster size between 500 and 3000. These cluster ions may be accelerated up to a maximum of 20 keV such that the energy per atom, or partition energy, can be varied from < 2 eV (5 keV, Ar3000+) to 40 eV (20 keV, Ar500+). A subsequent ion channelling bend in the focusing column removes energetic neutrals. The beam is then focused to a minimum spot size of 250 μm on the sample. Scan plates allow the beam to be rastered across the sample surface to create an even depth profile.

The ability to generate Arn+ ions with different cluster sizes and acceleration energies means successful depth profiles can be generated from the greatest range of materials. Large clusters, where n > 2000, are useful for depth profiling organic layer systems whilst smaller clusters of n=500 accelerated to high energies have been shown to be necessary in retaining chemistry of inorganic materials during depth profiling and sample cleaning.

Ar+ monatomic operating mode

The ion source can be operated in monatomic Ar+ ion mode for conventional depth profiling inorganic and metallic samples. The sputter yield for this class of materials is known to be much higher for monatomic than cluster ions making Ar+ monatomic mode important for depth profiling in realistic experimental times. Ion acceleration voltage can be varied between 500 eV and 8 keV.

Hardware & software

The standard configuration provides differential pumping of the ion source by two dedicated turbo molecular pumps with additional pumping provided by the sample entry chamber. An automated gas handling manifold is provided to supply both high and low pressure for cluster and monatomic modes respectively.

The ion source control unit is computer controlled through the ESCApe software allowing unattended operation of and switching between Arn+ cluster and Ar+ or He+ monatomic modes. For routine operation the User interface allows simple recall of standard operating methods for sample cleaning and depth profiling in cluster and monatomic modes. Operating parameters of the ion source are continuously displayed allowing key parameters to be monitored along with a vacuum mimic diagram showing the status of valves and pumps.

Applications

Inorganic depth profiling

Small cluster, high energy depth profiling

It is known that the sputter yields from inorganic materials are low when using gas clusters. This challenge can be mitigated by using small clusters with high beam energy. Here we contrast the use of 5 keV monatomic Ar+ with 20 keV Ar1000+ ions for sputter depth profiling a Lithium phosphorous oxynitrde ALD thin film where the Li distribution through the film is of interest. The high acceleration voltage in cluster mode ensures that the depth profile was completed in a practical time scale.

There is a distinct difference between the two profiles. Under monatomic bombardment there is an initial increase in Li concentration after the first etch cycle – a consequence of removing surface contamination – then a subsequent decrease in Li into the bulk of the film reaching a steady-state, shown in figure 1(a). Near the LiPON interface with Si substrate the Li concentration increases. By contrast when profiled 20 kV Ar1000+ ions the profile shows a different distribution of Li, figure 1(b). An initial increase in Li concentration is shown after the first etch however there is no subsequent decrease. Interestingly no accumulation of Li was seen at the interface with the Si substrate. A comparison of the Li concentrations profiled using two different ions is shown in figure 1(c).

The different results are attributed to positive charge build-up in the near surface region from implanted monatomic Ar+ ions. Charge build-up repels the small, mobile positive Li ions in the surface further into the bulk resulting in an underestimation in surface quantification. Repulsive bulk migration also accounts for the increase in Li concentration at the interface with the Si substrate. The light ions are unable to penetrate through into the Si metal and native oxide and instead accumulate at the interface.

Nanostructured multilayer materials

Large cluster, high energy depth profiling

Nanostructured multilayer materials have emerged recently as a distinct class of super-hard materials which have found use as coatings for cutting tools and turbine coatings. They consist of nanometer repeating layers assembled via physical vapour deposition to form superlattices. An example of such a material is TiN (7nm) / CrN (3nm) multilayer with 100 repeat units which has been shown to have high resistance to oxidation and superior mechanical properties.

The conventional approach to depth profiling this sample would be to use 500 eV monatomic Ar+ ions. The profile is shown in figure 2(a). It is immediately apparent that there is a loss of interface resolution after 6 repeat units (12 layers) due to penetration of the monatomic Ar+ ions into the material resulting in mixing of the layers. This was supported by the observation of Ar in the photoemission survey spectrum during the depth profile.

The same sample was profiled using high energy, large clusters (20 keV, Ar2000+). The use of the high ion acceleration voltage ensured that the yield volume per incident ion was as high as possible so that the depth profile was completed in an overnight experiment. Figure 2(b) shows the successful depth profile with retention of the layer structure throughout the 100 layer coating. In contrast to the monatomic profile Ar incorporation into the sample was not observed for this Ar2000+ cluster profile.

Organic multilayer depth profile

Small cluster, medium energy depth profiling

Thin film polymer structures are finding an increasing number of applications including optical filters and reflectors, organic electronics and drug delivery systems. The use of gas clusters has allowed the sputter depth profiling of this class of materials, where the chemistry of the polymer is retained throughout the profile. Here, 10 keV Ar1000+ ions were used to depth profile through a 50 layer multilayer Bragg reflector comprising spin-coated polystyrene (PS) and polyvinylpyrolidone (PVP). Characterization by complimentary techniques [1] confirm the PS and PVP layers were 328nm and 288nm respectively such that the multilayer material was >15um thick. Figure 3(a) shows the sputter depth profile through the entire structure to the glass substrate. The layer structure is retained throughout the depth profile and it is evident that the fabrication of the structure resulted in uniform layer thickness for each respective polymer layer. Figures 3(b) and (c) show the C 1s spectrum for layers 35 and 36 respectively, demonstrating that the chemistry of the polymer is also retained during the sputtering process.

Conclusions

The multimode gas cluster ion source provides the capability to depth profile polymer, inorganic and metallic samples through a choice of giant gas cluster or monatomic argon ions. Easy control of both the cluster size and ion energy allows the appropriate partition energy to be used for the application whilst maintaining suitable sputter yields per incident ion. Small clusters at high energy (20 keV, Ar1000+) are useful for depth profiling inorganic materials and demonstrate significantly improved retention of stoichiometry when compared to monatomic Ar+ profiles. Large, lower energy clusters (5 keV, Ar3000+) are employed for removal of surface contamination of polymer materials whilst medium energy, large clusters (10 keV, Ar3000+) are suitable for extremely deep profiling of organic materials.

References

[1] Smith EF, Counsell J, Bailey J, et al. Sample rotation improves gas cluster sputter depth profiling of polymers. Surf Interface Anal. 2017, https://doi.org/10.1002/sia.6250

Enquire about Gas Cluster Ion Source (GCIS) : Minibeam 6

Get in touch to find out more or contact your local distributor directly.